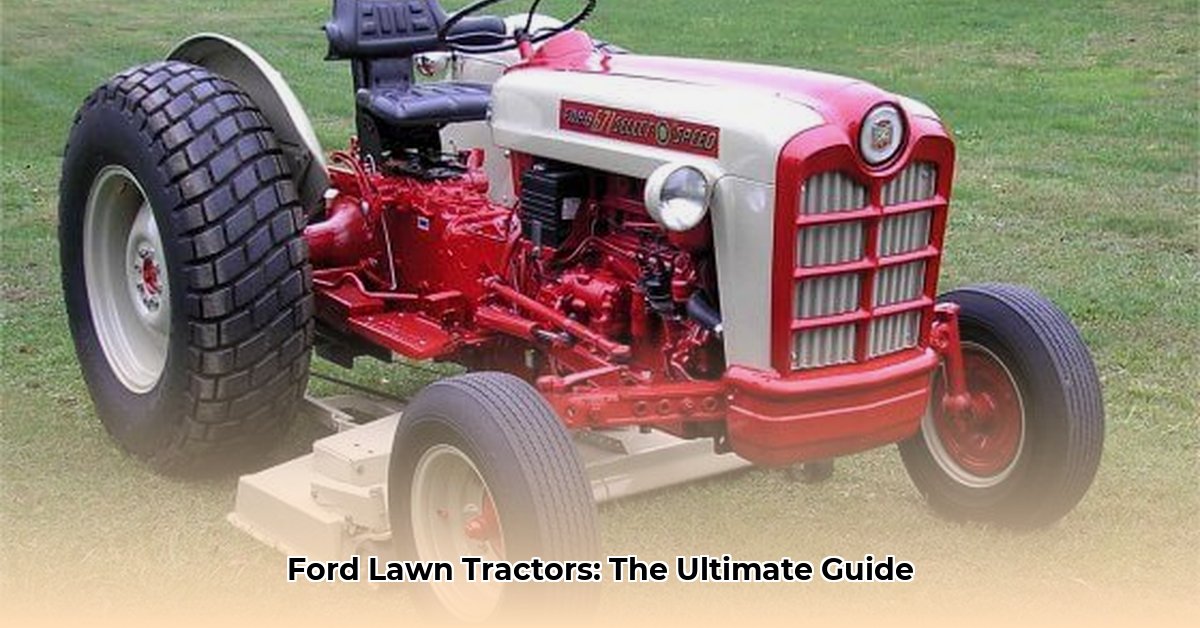

Ford's name is synonymous with automobiles, but their legacy extends to the surprisingly robust world of lawn tractors. These weren't simply mowers; they were built with Ford's renowned emphasis on durability and performance. This article explores the history of Ford lawn tractors, examining their technical specifications, and considering their sustainability implications within the broader context of agricultural technology and environmental responsibility. We'll delve into their rise, fall, and unexpected resurgence, analyzing key models and exploring how these machines fit into the evolving landscape of sustainable lawn care. For more on modern lawn tractors, check out this helpful resource: Lowes Lawn Tractors.

A Partnership Approach: Ford's Strategy and its Impacts

Ford's entry into the lawn tractor market wasn't a solo venture. Instead, they strategically partnered with established manufacturers like Jacobsen, Gilson, and Toro. This collaborative approach provided immediate access to manufacturing expertise and market penetration, a mutually beneficial arrangement offering Ford brand recognition and substantial contracts for their partners. This outsourcing model, common in various industries, presented inherent risks and challenges, a fact that will become increasingly evident as we examine Ford's history in this sector.

The Rise and Fall (and Rise?) of a Green Giant

From the 1970s to 1988, Ford lawn tractors were a familiar sight. The trusted Ford name implied quality, promising reliability and performance. However, internal restructuring at Ford led to the sale of its agricultural machinery division, including the lawn tractor line, to Fiat. This resulted in the phasing out of the Ford branding and the integration of these models under the New Holland banner. This transition highlights the dynamic nature of brand partnerships and market shifts, adding a layer of complexity to the narrative of Ford’s lawn tractor legacy.

Technical Deep Dive: The Ford LGT-145

The Ford LGT-145 serves as a prime example of Ford's lawn tractor offerings. While precise specifications vary depending on the source, this model typically featured a [insert engine size if available from draft] engine and offered a reliable [insert horsepower if available from draft] horsepower output, substantial for its time. But beyond horsepower, the LGT-145's sustainability poses intriguing questions. Were the parts readily available, facilitating repairs and extending the tractor's lifespan, minimizing environmental impact? Or was this model designed for shorter-term use, eventually destined for disposal? These considerations are crucial for assessing the full environmental footprint of the machine.

Sustainability: A Broader Perspective

The sustainability of lawn tractors extends far beyond fuel efficiency, encompassing the entire life cycle of the machine. This includes:

- Manufacturing: The energy consumption and emissions involved in the production process.

- Operational Efficiency: Factors influencing fuel consumption and operational lifespan.

- Repair and Maintenance: The availability of parts, ease of repairs and their impacts on longevity.

- Disposal: The methods and environmental consequences of disposing of the tractor at the end of life.

How did Ford address these factors in their lawn tractor designs? Further investigation is necessary to accurately assess their overall environmental impact.

Areas for Future Research: Unanswered Questions

To fully comprehend the environmental impact of Ford lawn tractors, several crucial research areas need to be addressed:

- Comparative Analysis: Direct comparisons between Ford models like the LGT-145 and contemporary models from Jacobsen, Gilson, and Toro would illuminate Ford’s design choices and market positioning.

- Life Cycle Assessment (LCA): A comprehensive LCA would trace the environmental consequences from resource extraction through manufacturing, use, and disposal, offering a holistic evaluation.

- Production Data: Detailed production figures for various Ford lawn tractor models would enhance our understanding of their overall market impact.

- Archival Research: Examining dealer records and archival materials could unearth vital details and fill historical knowledge gaps.

By addressing these points, we can construct a more complete and nuanced picture of Ford's contribution to the agricultural equipment landscape and their commitment – or lack thereof – to sustainability principles.

Sustainably Maintaining Your Vintage Ford Tractor: A Guide

Owning a vintage Ford lawn tractor is a testament to its enduring appeal. However, maintaining these machines requires a sustainable approach.

1. Understanding Your Machine:

Begin by identifying your specific model. Owner’s manuals, often available online, provide essential details on maintenance schedules and part specifications. Thorough understanding of the model ensures appropriate care and minimizes unnecessary part replacements.

2. Preventive Maintenance:

Regular maintenance is paramount. This includes regular oil changes (using the correct oil type and recycling used oil), air filter inspections and replacements, spark plug replacements (to improve efficiency and reduce emissions), blade sharpening (to optimize cutting performance and reduce fuel consumption), and regular belt inspections (to prevent breakdowns and ensure optimal power).

3. Sustainable Parts Sourcing:

Finding parts for vintage equipment can be challenging. Utilize online communities, local dealers, repurposing, and repair over replacement strategies to minimize waste and resource consumption.

4. Eco-Friendly Practices:

Consider using biodegradable engine oil, ensuring proper fuel storage to prevent spills, and choosing environmentally responsible disposal options when the tractor reaches its end-of-life. These actions actively reduce the environmental footprint of ownership.

Conclusion: Sustainability and the Legacy of Ford Lawn Tractors

Ford's foray into the lawn tractor market, though ultimately short-lived under their own brand, left an undeniable mark. Understanding the technical specifications and the wider sustainability implications of their models requires a multifaceted approach, using historical research, technical analysis, and an awareness of environmental impact across the entire product lifecycle. Responsible ownership and maintenance are key to preserving these machines' legacy while minimizing environmental impact.